There are three valences of Chromium: 1) Chromium—safe to humans, 2) Trivalent Chromium—safe and an essential element in humans and 3) Hexavalent Chromium—highly carcinogenic to humans. Erin Brockovich’s fame and fortune came from Erin’s dogged and tenacious quest to defeat Pacific Gas and Electric Company (PG&E) in the poisoning of the residents of Hinckley, CA by its use of Hexavalent Chromium in its Hinckley facility. PG&E stored Hexavalent Chromium in their cooling towers as a coolant and to prevent rust from forming in its natural gas compressors. Then, they discharged and stored the residual Hexavalent Chromium liquid in unlined ponds contaminating soil, subsequently, the Hexavalent Chromium percolated into the water table, which caused life suffering-cancerous diseases to the residents of Hinckley, that would eventually lead to death. Before Erin came along PG&E was buying up homes in Hinckley and paying medical bills for all the sick residents. This was the cheapest way out for PG&E, relieving them of all liabilities. Ultimately, PG&E, a $21 billion company, settled two Hexavalent Chromium lawsuits in Hinckley, CA for $333 million and Kettleman Hills, CA for $335 million (Erin Brokovich, Wikipedia).

Regulating Hexavalent Chromium

Hexavalent Chromium has caused a mired amount of suffering and deadly diseases that range from asthma, liver disease, lung cancer, stomach cancer, skin cancer, cardiovascular disease, as well as many other deadly cancerous effects to external and internal human organs. Hexavalent Chromium cancer clusters can be isolated and identified to specific areas of our environment, such as former Chromium manufacturing sites and those dumping sites, as well as in coal ash and their unlined dumping sites.

Although the EPA has no standard that regulates the cleanup of Hexavalent Chromium, it does regulate the permissible limits for Hexavalent Chromium in soil and Water. The EPA, in order to ensure safe drinking water, has an enforceable drinking water standard of 0.1 milligrams per liter (mg/L) or 100 parts per billion (ppb) for total chromium, which includes Hexavalent chromium and Trivalent Chromium. In fact, California has set its regulatory limit of 10 ppb for Hexchrome, which went into effect July 1st. A national set by EPA won’t be far behind.2 The EPA’s permissible limit for Hexavalent Chromium in soil would have to be detected by a Toxicity Characteristic Leaching Procedure (TCLP). When tested by TCLP the hazardous contaminant in the soil must be under 5µg/L.

EPA’s Exposure Limits

Hexavalent Chromium’s allowable permissible exposure limit (PEL) in an eight-hour work period is a Total Weight Average (TWA) of 5 micrograms per cubic meter(µg/m3), meaning that over the course of any 8-hour work shift, the average exposure to the worker cannot exceed 5µg/m3. The Action Level—the level of exposure to a harmful substance or otherhazard present in a work environment or situation at which anemployer must take therequired precautions to protect the workers—is normally one half of the permissible exposure limit. For Hexavalent Chromium the action level is setat 2.5 µg/m3 calculated as an eight-hour TWA. Exposures above the Action Leveltrigger specific requirements, and exposures above the PEL trigger additionalrequirements. The substantive provisions of Hexavalent Chromium standard aredescribed below.

.

Exposure Monitoring andDeterminations

Each employer who has a workplace or work operation covered by Hexavalent Chromium standards must determine the eight-hour TWA exposure for each worker exposed to Hexavalent Chromium. To comply with this provision, employers can choose between two options for performing exposure determinations:

- A scheduled monitoring option

- A performance-oriented option

When monitoring for Hexavalent Chromium, employers must use a method of monitoring and analysis that provides values within plus or minus.

Exceptions

The Hexavalent Chromium standards do not apply in three situations:

- Exposures that occur in the application of pesticides

- Exposures to Portland cement

- Where the employer has objective data demonstrating that a material containing Hexavalent Chromium or a specific process, operation or activity involving Hexavalent Chromium cannot release dusts, fumes or mists of Hexavalent Chromium in concentrations at or above 0.5 µg/m3 of air as an eight-hour TWA under any expected conditions of use

Concern for the Worker

The aforementioned EPA exposure limits and exceptions started to make me think and ask myself the question: what do current chrome plating manufacturers do to protect the worker?

Chrome plating is certainly a thriving industry, just look at a decked out Harley Davidson motorcycle or any other motorcycle with chrome. I’ve owed a number of motorcycles and I believe I’ve spent more time cleaning them and polishing the chrome than riding them. Given the fact that there is still existing chrome plating businesses, I started to call manufactures that dealt with chrome and chrome plating.

The first manufacturer I called was in business for 30 years. His company just ground and made chrome particles, not from Hexavalent Chrome and not from Trivalent Chrome, but the manufacturer used pure Chrome, which is not toxic, without incidence of worker disease. For protection, the manufacturer’s shop workers wore coveralls that were washed on regular basis and respirators for dust protection while either size reducing or grinding the Chrome to specific particle sizes. The manufacturer used all precautionary measures and followed all environmental, health and safety regulations.

The second manufacturer I called said they switched from using Hexavalent Chromium in their chrome plating operations to the safe-nonhazardous Trivalent Chromium.

The third manufacturer I called used Hexavalent chromium in its plating operations. I asked if the workers wore protective clothing and respirators; his answer was no. I asked how the workers were protected; his answer was powerful fume hoods over the plating vats that allowed a safe working environment. He also explained that any sludge left over from the plating operation was sent to be incinerated, therefore, avoiding any cradle-to-grave liability.

If all industry that handled hazardous, toxic and regulated wastes thought to avoid cradle-to-grave liability, our environment and children would thrive in the future and not have to deal with the environmental problems left to them. This brings me to Hexavalent Chromium in soil left to our generation to deal with, as well as the problems with the cleanup processes that have been tested to rid our environment of the deadly chemical compound.

Hexavalent Chromium in Soil

Hexavalent Chromium in soil comes from Chromium ore processing residue that was used as fill, dumped on sites close to or behind the manufacturing processing facility or used as an equipment rust inhibitor that was dumped in unlined ponds. Eventually these sites became Superfund sites that needed to be cleaned up leaving the taxpayer to bare the financial burden.

Hexavalent Chromium has been found on at least 1,127 of the 1,669 National Priorities List sites identified by the EPA. In New Jersey there are 113 sites contaminated with Hexavalent Chromium in soil.

For example, the Port of Baltimore, renamed the Helen Delich Bentley Port of Baltimore, is approximately 580 acres of which approximately 148 acres of soil is contaminated with Hexavalent Chromium. It was used as fill generated by Allied Signals chrome plating operation. The Hexavalent Chromium tailings were dumped into the Port to expand the working area.

According to Earth Justice (www.earthjustice.org), “…unlined coal ash dump site’s leachate has Hexavalent Chromium that precipitates into the local water table … The federal government does not currently regulate the disposal of coal ash, the toxic waste created by coal-fired power plants that’s known to contain potentially dangerous levels of heavy metals, combustion byproducts and radioactive elements … The report identifies 28 coal ash dump sites from Massachusetts to Nevada where Hexavalent Chromium has been detected in the groundwater at levels exceeding federal or state standards. Most of the sites are at power plants, though the list also includes landfills and a golf course in Chesapeake, VA that was built on coal ash fill. Given the lack of comprehensive federal monitoring requirements for coal ash disposal facilities, the report says that these 28 sites are likely just ‘the tip of the iceberg.’” Given the above facts, Hexavalent Chromium is a scary and deadly carcinogen that must be treated to a humanly safe state.

Hexavalent Chromium Disposal and Treatment Options

The first option is to send Hexavalent Chromium in soil to a landfill that will take it and is able to treat it to meet the required standard set by the landfill. If it can’t be treated to its required level, the landfill will not take it. The limited amounts of landfills that take Hexavalent Chromium are in remote areas far from the contaminated sites. Trucking and treatment are a huge expense per ton. Also, landfilling does not take the cradle-to-grave liability away.

The Helen Delich Bentley Port of Baltimore has paved over the portion contaminated with Hexavalent Chromium soil with asphalt and cement and has relined its sewer disposal system to minimize the discharge of Hexavalent Chromium into the Bay.

There are problems with paving over the Hexavalent Chromium in soil: the first is that the Hexavalent Chromium in soil has a high pH and tends to be unstable due to the combination of Carbon Dioxide + Calcium Oxide = Calcium Carbonate that causes the reactive tailings to buckle the pavement or rise up through the pavement; the second is wear and tear on the pavement from heavy industrial traffic; the third is digging into the pavement for a new structure placement or an underground repair, disturbing the Hexavalent Chromium soil, causing it to become airborn.

Hexavalent Chromium in soil has many other constituents and contaminates in its matrix. Many treatments have been tried, but do not attack the complete matrix to transform the Hexavalent Chromium to Trivalent Chromium. These treatments include, but are not limited to, Solidification, In Situ with Calcium Polysulphide, Soil Washing, Electrokinetics, Bioremediation, Electron Energy, Extraction, Calcium Polysulfide Remediation and Sol-Gel Stabilization and a few others.

There is one emerging technology that fully attacks the matrix of Hexavalent Chromium in Soil consistently turning into Trivalent Chromium, holds the pH to 7 and does not swell or buckle

Chromium Treatment: Hexavalent Chromium to Trivalent Chromium Test Results

Overview

Samples of Hexavalent Chromium were treated to convert Hexavalent Chromium to Trivalent Chromium. The basis for the treatment is outlined below:

- The soil and rocks were crushed through a shredder and mixed together to make a homogeneous sample.

- After doing several laboratory tests, different combinations of chemicals in combination were used to treat the homogeneous sample.

- pH was checked on each sample of Hexavalent Chromium soil before, pH 12-13, and after conversion of the Hexavalent Chromium to Trivalent Chromium solid, and residual liquids and solids easily adjusted to pH 6-7.

- Samples were filtered and the solids sent to the lab for total Chromium content, Trivalent Chromium, and Hexavalent Chromium analyses (7196, 6010B analysis).

- A swelling study was also done to test if the treated Chromium soil would swell. Photos of the homogeneous Chromium sample expansion study are exhibited in Attachment A. There was no swelling of the converted Hexavalent Chromium to Trivalent Chromium soil over a six month period, and again, checked approximately a little over two years later 4/2/2014, showed no buckling or swelling of the converted Hexavalent Chromium to Trivalent Chromium soil, covered or uncovered.

All test results analyzed by EMSL Analytical, Inc. proved the conversion of Hexavalent Chromium (none detected in all the results) to Trivalent Chromium.

Results

The 7196, 6010B test result of total calculations of the conversion of Hexavalent Chromium to Trivalent Chromium, bench top samples, are consistent with all previous bench top testing exhibited in Table 1, page 5. The 7196, 6010B test result of total calculations of residual liquid filtered from converted Hexavalent Chromium to Trivalent Chromium treated solids is exhibited in Table 2, page 5. The 7196, 6010B test results of total calculations of the converted Hexavalent Chromium to Trivalent Chromium tested in the Pilot Plant exhibited in Table 3, page 5.

Captions

Table 1

Bench Top Sample Analyzed by 7196, 6010B Test. NOTE: 7196, 6010B calculations are in parts per million.

Sample ID

|

7196, 6010B

|

Sample CS

|

Cr3: 11000, Cr6: ND

|

Table 2

Filtered Residual Liquid Analyzed by 7196, 6010B Test.

Sample ID

|

7196, 6010B Calculation

|

Sample CL

|

Cr3: ND, Cr6: ND

|

Table 3

Samples Tested in the Pilot Plant Analyzed by 7196, 6010B Tests. NOTE: 7196, 6010B calculations are in parts per million.

Sample ID

|

Samples of Hexavalent Chromium

|

7196, 6010B Calculations

|

RM1

|

Test 1

|

Cr3: 11000, Cr6: ND

|

RM2

|

Test 2

|

Cr3: 9200, Cr6: ND

|

RM3

|

Test 3

|

Cr3: 8200, Cr6: ND

|

RM4

|

Test 4

|

Cr3: 7400, Cr6: ND

|

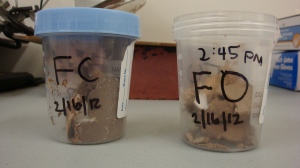

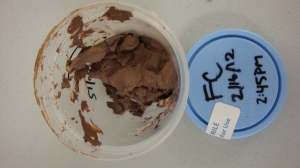

Figure 1 – 3

Photos of the Converted Chromium Soil Expansion Study, No Swelling

- Chromium Soil with Sample FC (Filtered Close Lid) and Sample FO (Filtered Open with No Lid)

- Top View of the Chromium Sample with the Closed Lid (No Swelling)

- Top View of the Chromium Sample with No Lid, Open Top (No Swelling)

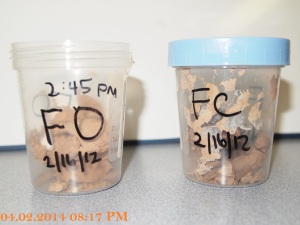

Figure 4 – 5

The photos below taken approximate two years later, 4/02/2014 at 8:17PM show no signs of swelling or buckling.

- Side View of Chromium Soil with Sample FC (Filtered Close Lid) and Sample FO (Filtered Open with No Lid)

- Top View of the Chromium Sample with the Closed Lid (No Swelling) and Top View of the Chromium Sample with No Lid, Open Top (No Swelling)

Images courtesy of ABCOV®

Conclusion and Benefits of Changing Hexavalent Chromium in Soil to Trivalent Chromium in Soil:

The results of the aforementioned emerging Hexavalent Chromium in soil to Trivalent Chromium in soil technology will solve a multiple of the problems that may be encountered with other treatments of Hexavalent Chromium in soil to Trivalent Chromium in soil:

- The process chemicals adjust the pH to a neutral status, therefore stopping any future swelling or buckling of the soil.

- Once changed from Hexavalent Chromium in soil to Trivalent Chromium in soil it can be put right back into the site, avoiding the cost of buying and trucking fill back into the site.

- The Hexavalent Chromium in soil to Trivalent Chromium in soil process treatment is done right on site avoiding long distance trucking of Hexavalent Chromium in soil through neighborhoods and over highways, avoiding any possible exposure and possible liability.

- Using this merging technology will stop all cradle – to – grave liability created by the landfilling of Hexavalent Chromium in soil by insuring the generator from being a Potential Responsible Party under the Superfund Act.

- Hexavalent Chromium in soil to Trivalent Chromium in soil will stop the Hexavalent Chromium from becoming dangerously air borne or, more deadly, migrating into the water table.

- The process incorporates the three Rs: Reduce, Reuse and Recycle.

- Most importantly, the aforementioned process attacks the Hexavalent Chromium matrix/binder completely to insure the change from Hexavalent Chromium in soil to Trivalent Chromium in soil.

Why Treat Hexavalent Chromium in Soil to Trivalent Chromium on Site

Landfills that allow Hexavalent Chromium in soil to be dumped must treat Hexavalent Chromium down to a 3 ppm, “Waste Management Site, Emelle, Al”. If the ppm is too high when entering the landfill and the Hexavalent Chromium in soil cannot be treated, it is sent back to its generator, a costly procedure.

As previously mentioned above there are 113 sites in New Jersey a distance of approximately 1,100 miles or a 16 to 18 hour drive from Jersey City, N.J. to Emelle, Al.

Between the cost of trucking, taxes and gas charges for the trucking of the Hexavalent Chromium in soil to the dump site, as well treatment, if possible, at the dump site and the cradle – to – grave liability carried through perpetuity, it pays to treat the Hexavalent Chromium in soil to Trivalent Chromium in soil on site.

Further, there are a very limited amount of hazardous waste landfills that will take Hexavalent Chromium in soil and they are becoming scarcer and scarcer.

US EPA Report: Valuing Potential Environmental Liabilities for Managerial Decision – Making: “All Landfills and Leachate Systems Will Fail” and “By Definition, All Environmental Liabilities Involve Future Costs.

Given the above quotes by EPA, we are never going to see the end of poisoning ourselves as long as we continue to landfill hazardous, toxic and regulated disease-causing, deadly wastes instead of finding and employing environmental technologies to treat these wastes.

“The United States is sinking under a tidal wave of waste with no effective government plan in sight. It is left for us to act (Zero Waste America)!”